With Tesla it is sometimes hard to separate the truth from the hype. The latest rumour or story- it is hard to tell which it is- to emerge from the Californian electric car manufacturer is that it is having more production problems, which look awfully like they are production logistics problems.

The American television channel, CNBC reported that problems include “Tesla needing to make some of the batteries by hand and borrowing scores of employees from one of its suppliers to help with this manual assembly”. The source was apparently workers from the ‘Giga Factory’ in Nevada.

Tesla replied to the suggestions by saying, “until we reach full production, by definition some elements of the production process will be more manual.”

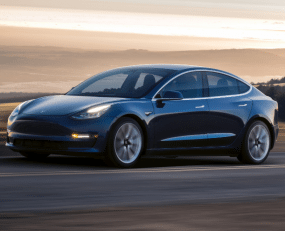

The underlying issue is that Tesla is moving from building low volume, expensive sports cars to building its new ‘Model 3’ sedan, designed to be produced in the hundreds of thousands and at a comparatively low price of US$35,000.

With such a shift comes problems.

For example, Tesla is hoping to use a high level of automation on its battery production line. At high volume, automation can offer the possibility of reduced units costs. However, the underlying processes are different from those used to produce cars at lower volume. The danger will be that a mixture of the two will result in bottlenecks and inventory shortages. Such problems are very familiar to logisticians in the automotive sector. Toyota came to understand the nature of such problems, emphasising the importance of ‘Heijunka’, or ‘levelling’ in any production process; that is ensuring that activity on the production line (or indeed the supply chain) are progressing at the same-speed and at a constant, predictable speed.

Such organisational problems are not uncommon in the introduction of new model types or production technologies in the automotive, or indeed other industries. Even the largest and most experienced companies can encounter such problems, for example Volkswagen in its introduction of the MQB platform.

The problem that Tesla has is its ambition. Introducing new technology is difficult and introducing it to a tight schedule is very difficult.

Source: Transport Intelligence, February 1, 2018

Author: Thomas Cullen

|

|

|